St. John Compressor Station Project

A proposed natural Gas project

TC Energy is one of North America’s leading energy infrastructure companies with operations in natural gas and power industries.

The ANR Pipeline Company (ANR), a subsidiary of TC Energy, is preparing to replace natural gas compressor facilities at its St. John Compressor Station located in Lake County, Indiana, to increase the reliability, safety, and long-term integrity of the compressor station and ANR’s system.

Specifically, the proposed Project includes replacing seven existing obsolete compressor units with two Solar Turbines Taurus-70 units and one Solar Turbines Mars-100 unit.

The modern turbine compressors, which operate smoother with less vibration, will reduce emissions and noise levels at the station once complete.

The system will also operate more efficiently to meet ongoing demand for natural gas to provide power and heating to homes, while lowering emissions.

Pre-construction activity is targeted to begin in June 2024, with an estimated completion date of December 2025.

Fact & Figures

Modern turbine compressors will reduce greenhouse gas emissions

Lower vibration will reduce operating noise

Increased reliability and safety of St. John Compressor Station

Estimated project timeline

Construction preparation

June 2024

Construction begins

August 2024

In-service

Q3 2025

Land restoration completion

Q4 2025

Dates shown are based on current understanding of the facts and are subject to change.

CONSTRUCTION

All Project construction activities, including the installation of the new compressor units, will be confined to our existing property.

The anticipated Project construction hours will typically be: Monday to Friday - 7 a.m. to 5 p.m., Saturday - 8 a.m. to 5 p.m. and Sunday - 9 a.m. to 5 p.m.

Select portions of the Project may occasionally extend beyond regular construction hours due to the nature of work. Should this occur, the community will be informed in advance, and the specific atypical construction hours will be detailed in the Construction Updates section below.

The first working hour will be utilized for daily preparations and should have minimal noise impacts.

Mitigative noise measures, including an additional wall barrier and white noise back-up alarms, will also be put in place.

Stay informed on recent developments by visiting our latest Construction Updates below.

November 7, 2025

Concrete and demolition work continues as part of ongoing site construction. We understand that elevated noise levels are disruptive to the surrounding community, and that's why our on-site workers have implemented additional steps to mitigate noise occurring at the site. We are also working to mitigate the noise by using alternate methods such as plasma cutting to complete the demolition. Plasma cutting may or may not generate smoke depending on the wind direction.

Some elevated levels of noise will continue during normal business hours (Monday through Friday), as the use of concrete-breaking equipment remains necessary to remove construction debris from the site. TC Energy is committed to concluding the demolition work as quickly and safely as possible.

Neighboring landowners with questions should call the landowner hotline at 877-287-1782.

September 5, 2025

Concrete and demolition work is scheduled to begin Monday, Sept. 8, as part of our ongoing site construction.

This phase of our project will involve the use of shears and concrete-breaking equipment to begin the process of removing construction debris from the site. As such, Residents and nearby businesses can expect elevated noise levels associated with this work.

This work will occur during normal business hours, Monday through Friday, commencing on or about Monday, Sept 8.

Simultaneously during the same timeframe, crews will also remove the temporary wall located on the northwest corner of the property next to White Oak Trail.

Neighboring landowners with questions should call the landowner hotline at 877-287-1782.

August 8, 2025

Construction activities continue to progress steadily across the site following the successful in-service of the three new compressor units in late July. Crews remain focused on daytime work during regular hours as we advance toward project completion, anticipated in late Q4 2025.

Key upcoming activities include a planned outage beginning Monday, Aug. 11, with testing activities scheduled for Wednesday, Aug. 13 that may generate increased noise during daytime working hours. Demolition work is scheduled to begin in early September, with concrete removal operations expected to produce daytime noise. Community notification will be provided prior to demolition activities, and all work will be conducted during normal business hours.

July 16, 2025

Construction activities continue to progress steadily across the site. Crews remain focused on daytime work during regular hours. Work on weekends is ongoing, with Saturday and Sunday efforts helping to maintain progress toward key project milestones.

Key developments include progress of landscaping work around the residential area near the model home, efficient site grading and gravel installation in multiple locations. Final improvements are being made to the compressor building and office building.

June 12, 2025

Construction activities continue to progress. Night shift operations have concluded, and crews are now focused on daytime work during regular hours. Weekend construction remains active, with work ongoing on Saturdays and Sundays to maintain momentum on key project milestones.

In the residential area near the model home, sidewalk repairs have been completed. Landscaping work, including seeding and restoration efforts, is scheduled to follow in the coming weeks to fully restore the site.

May 22, 2025

- Night Shift: Operations will conclude at the end of this month.

- Day Shift: Sidewalk repairs continue in front of the model home at 12444 Patnoe.

- Today (Thursday, May 22): Removal of the existing sidewalk is scheduled.

- Tomorrow (Friday, May 23): New concrete will be poured. Please use alternate pathways until the work is complete.

- Landscaping: Hydro-seeding and other landscaping activities are scheduled to begin next week.

May 1 - 31, 2025

Update: The project will continue to have additional work outside our standard construction hours. Work will be conducted from Monday through Saturday.

- Day shift: Work will include sidewalk repairs in front of the model home at 12444 Patnoe Drive and final restoration on the lot.

- Night shifts: Crews will start at 6 p.m. and continue until 4:30 a.m. All night shift work will be confined to the interior of the buildings to minimize any potential disturbances.

March – April 30, 2025

Update: The Project will continue to have additional work outside our standard construction hours to make up for weather-related delays. Work will be conducted from Monday through Saturday.

- The day shift: crews will arrive on site at 7 a.m. to perform preparatory work and attend pre-job meetings. Any activities that may generate noise will not begin until after 8 a.m. to minimize disruption. The day shift will conclude at 5 p.m., and a flagger will be present to assist with the shift change.

- The night shift: crews will start at 5:30 p.m. and continue until 4 a.m. All night shift work will be confined to the interior of the buildings to reduce any potential disturbances.

February 14, 2025

Update: The structural crews are working on completing our three new process buildings. The mechanical crews are installing exterior process piping, while the electrical crews are working inside the Compressor building, installing cables and conduits to our new compressors.

On Sunday, Feb. 16, and Sunday, Feb. 23, the Project will have additional work outside of our standard construction hours to make up for weather-related delays. We anticipate this work will occur between 9 a.m. and 5 p.m.

From March 3 to April 30, there will be night shifts from 5:30 p.m. to 5:30 a.m. No Sunday night shifts are anticipated. All work will be performed inside the buildings.

October 3, 2024

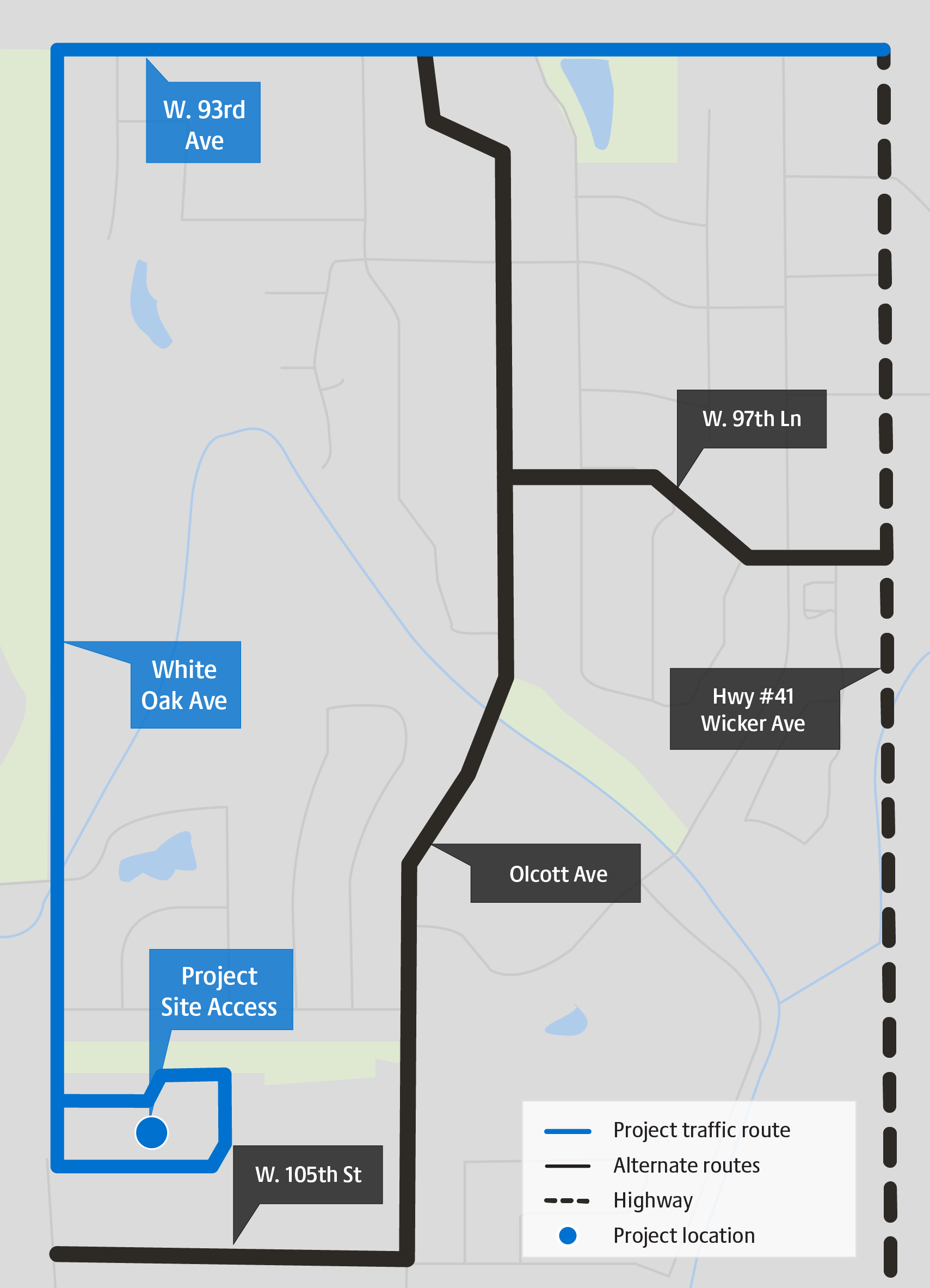

Update: The Project will mobilize oversize loads starting the week of October 7 through October 31. This will entail the use of police escorts and periodic road closures on White Oak Avenue for short durations.

On Wednesday, October 9, the Project must start work at 6 a.m. This is required to complete the type of work scheduled for this day. The Project will make every effort to minimize any potential impacts of noise and lighting.

Starting October 14 through October 28, the Project will have additional work outside of our standard construction hours. Due to the extended hours, there may be noise and visible lighting in the evening. This is necessary due to the welding process that is required for this phase of the Project. We do not anticipate evening work to exceed 8 p.m.

This phase also entails an outage of our facility. To minimize impacts to our customers, including NIPSCO, the Project must work for longer durations. Once this two-week phase is complete, the Project will return to its standard construction hours.

Impacted road: We anticipate that this activity will impact primarily the roads of West 93rd Avenue and White Oak Avenue.

Road closure: We do anticipate periodic closures on White Oak Avenue for short durations. We will abide by the required hours issued in our hauling permits.

August 26, 2024

Update: The Project has completed its pre-construction preparation activities. Starting the week of August 26, the Project will begin foundational work at the site including excavating and the installation of helical piles. These types of activities will require multiple trucks to enter and exit the area during our project work hours over the next three weeks.

Impacted road: We anticipate that activity will impact primarily the roads of West 93rd Avenue and White Oak Avenue.

Road closure: We do not currently anticipate any road closures but will utilize flaggers as needed.

August 13, 2024

Update: During the week of August 12, the Project will begin a full mobilization of equipment to our site. This will include the transportation of office trailers and heavy equipment. Most of the traffic flow will last approximately two weeks.

Impacted road: We anticipate that activity will impact primarily the roads of West 93rd Avenue and White Oak Avenue.

Road closure: We do not currently anticipate any road closures but will utilize flaggers as needed.

August 5, 2024

Update: During the week of August 5, preliminary construction preparation will continue at our Project site. This will include the continuation of slit trenching and hydrovacing. These activities are required to safely excavate around utilities and will produce noise during the work hours of our Project.

The Project also anticipates beginning the mobilization of office trailers.

Impacted road: We anticipate that activity will impact primarily the roads of West 93rd Avenue and White Oak Avenue.

Road closure: We do not currently anticipate any road closures but will utilize flaggers as needed.

July 15, 2024

Update: Preliminary construction preparation will continue at our Project site. During the week of July 22, we anticipate the start of slit trenching and hydrovacing. These activities are required to safely excavate around utilities and will produce noise during the work hours of our Project.

Impacted road: We anticipate activity will impact White Oak Avenue as select heavy equipment mobilizes to our Project site in addition to the commute of our contractors.

Road closure: We do not currently anticipate any road closures.

June 24, 2024

Update: Construction activity will begin on June 24 with dump trucks moving materials to and from the Project site.

Impacted road: We anticipate activity will impact White Oak Avenue.

Road closure: We do not currently anticipate any road closures.

Community benefits

Our projects offer long-term economic benefits and help strengthen local, state and national economies in three key areas.

Employment and business opportunities — As we move into the construction phase of any project, we require equipment operators, welders, mechanics, truck drivers, laborers and more. We also have a demand for local goods and services. Learn more about working with us at our Contractors, Suppliers and Vendors portal.

Annual revenue to support local services — Project construction results in tax payments to all levels of government. When the Project is operational, annual tax payments help support schools, hospitals, emergency services and other local programs vital to communities.

Supporting local communities — We have a rich history of giving back to local and Indigenous communities where we live and work. Our Build Strong community investment program builds strong and vibrant communities by providing grants and donations that support community groups and initiatives, as well as awarding scholarships to our future energy problem solvers. Visit TCEnergy.com/BuildStrong to learn more about our social impact program and how to apply for funding.

Introducing TC Energy

We encourage you to learn more about who we are and our approach to sustainability.

Frequently asked questions

Who is TC Energy and what do you do?

We’re a team of 7,000+ energy problem solvers working to move, generate and store the energy North America relies on. Today, we are taking action to make that energy more sustainable and more secure. We are innovating and modernizing to reduce emissions from our business, and we are delivering new energy solutions – from natural gas and renewables to carbon capture and hydrogen – to help other businesses and industries decarbonize too. TC Energy is an energy infrastructure company that for more than 70 years – and in this area, over 100 years – operated pipelines, storage facilities and power-generation plants that support life in the U.S., Canada and Mexico safely, reliably and quietly.

Are the Solar Turbines compressor station units solar powered?

No. Solar Turbines is the manufacturer of the compressor unit turbines, but they are not solar powered.

Why are you replacing the existing compressor station units?

By replacing the seven existing reciprocating compressor units with three modern Solar Turbines units, we can improve operational sustainability, decrease vibration, reduce greenhouse gas emissions and operational sound levels, while gaining maintenance and operational efficiencies and improving the reliability, safety and long-term integrity of the St. John Compressor Station and ANR’s Pipeline System.

How are you reducing greenhouse gas (GHG) emissions?

Replacement and modernization of older compressor units with more efficient units and modern technology will result in decreased emissions.

Are your compressor stations safe?

TC Energy’s ANR Pipeline System and related metering and compressor stations have operated safely for the more than 70 years. Safe and efficient natural gas delivery is a foundational value for TC Energy and its employees. Through more than a century of operating experience and technological advancement, we have developed one of the safest and most reliable energy transportation networks in the world. We monitor our system 24 hours per day, seven days per week, and are constantly utilizing the latest in technology to maintain the highest possible integrity standards.

How will you limit your environmental impact during construction?

New compressor station units and construction activities will be located on the existing St. John Compressor Station site. Construction will use a temporary workspace.

Ways to reach us

We’re here to answer your questions. For general questions you can contact us by email, but for a quicker response, please call us directly.

U.S. Projects Landowner Hotline

Write to us

700 Louisiana Steet

Houston, Texas 77002